Our Services

Prototype and Mass Production

Mass production in electronics means careful planning to keep everything smooth and efficient.

Read More

Supply Chain

Supply chain and procurement to keeping operations running smoothly.

Read More

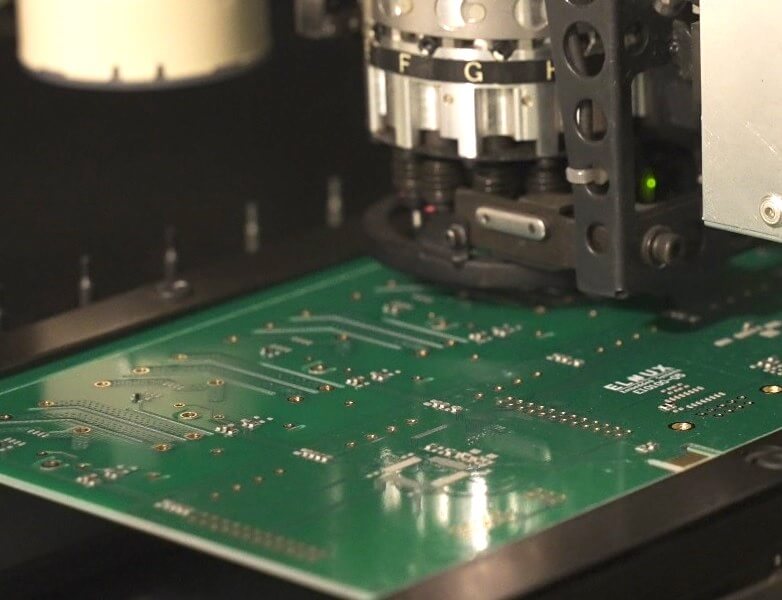

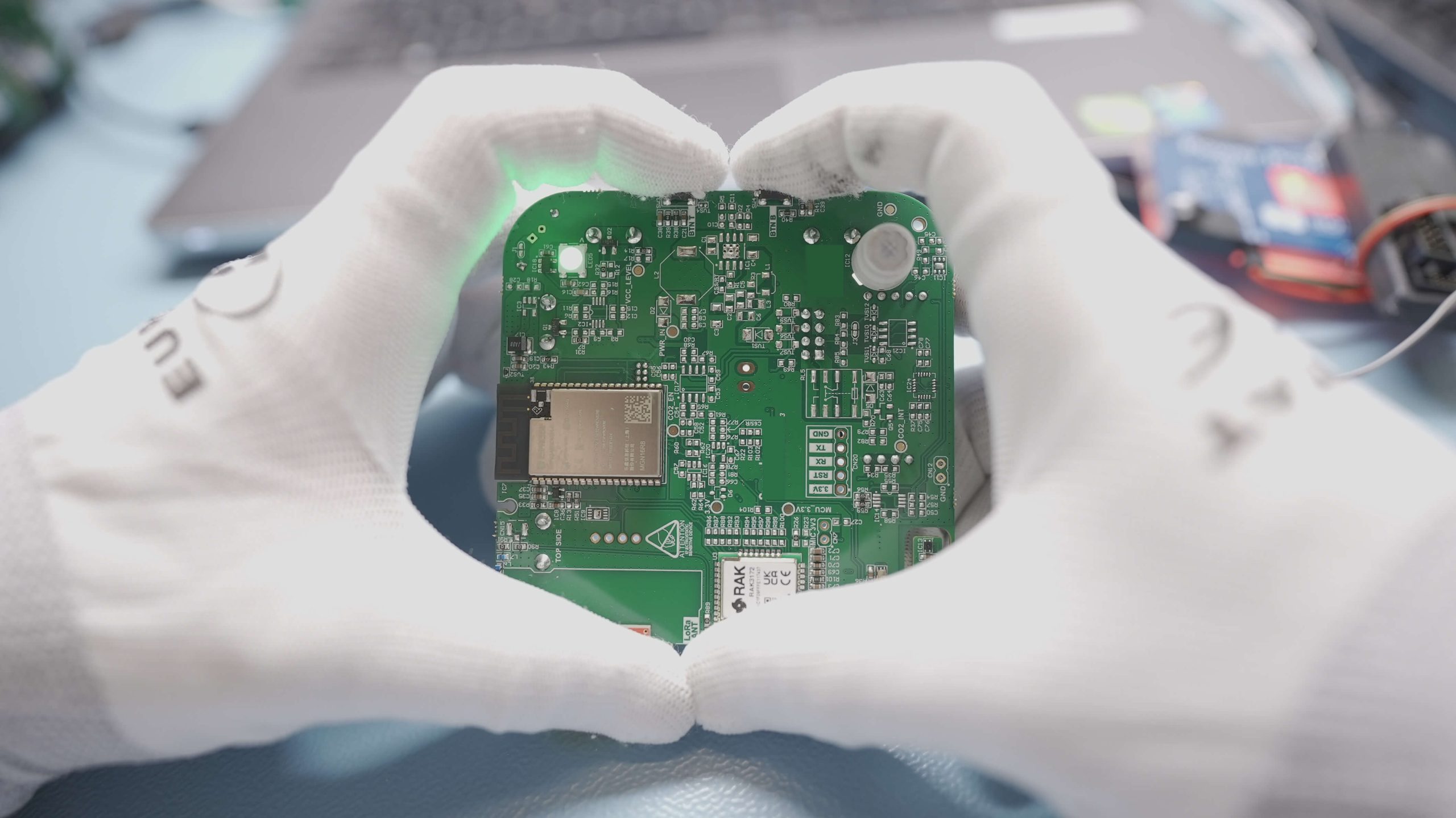

Printed Circuit Board Assembly

Reliable PCB Assembly – from design to function.

Read More

Final Product Assembly

Skilled workers use expert methods to build reliable, high-quality electronic products.

Read More

Battery Assembly

Power your electronics with precision and reliability.

Read More

Testing

Ensuring performance, precision, and reliability through every stage of production

Read More

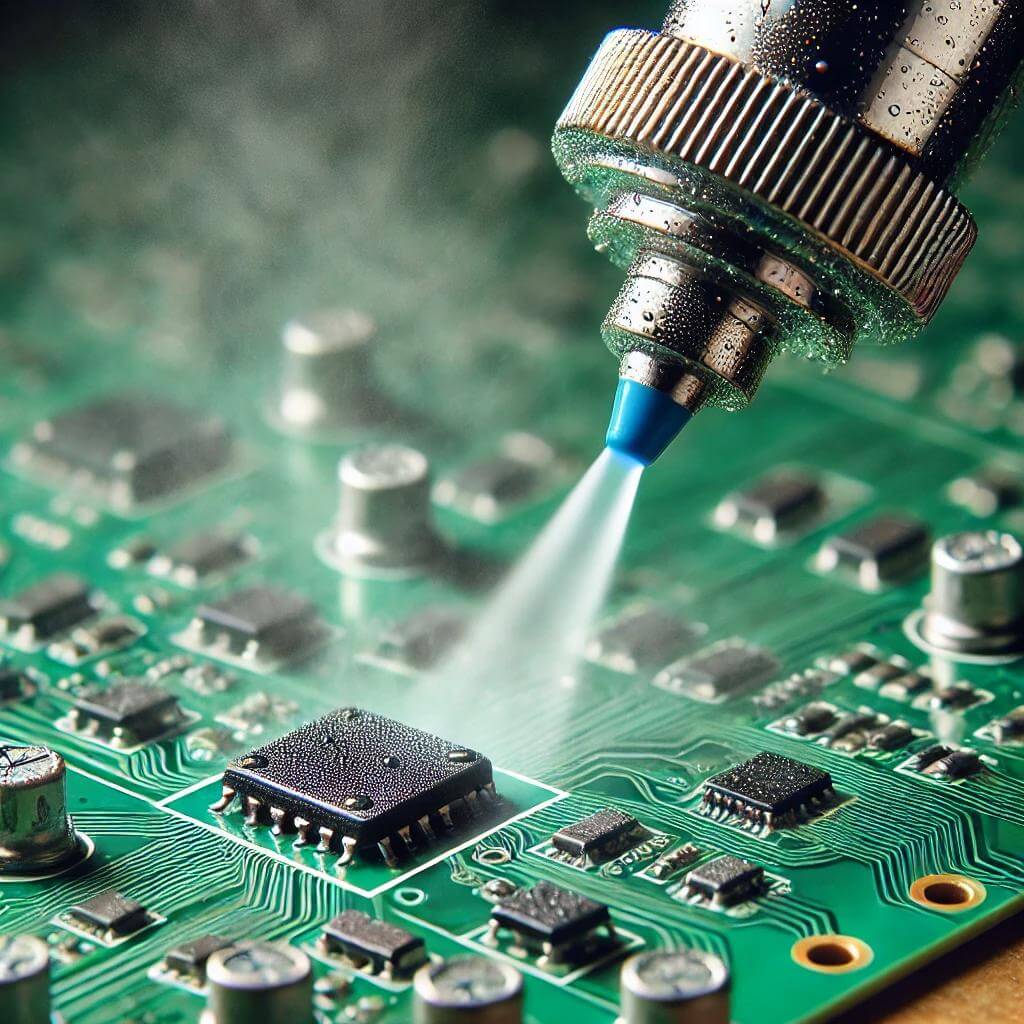

Conformal Coating

Conformal coating protects delicate electronic parts during manufacturing.

Read More

Logistics and Stocking

Smart logistics. Strategic stocking. Seamless production.

Read More

Support

We provide full manufacturing support to help improve your production and fix technical issues.

Read MoreFrequently Asked Questions

What steps are involved in mass production preparation?We begin with a detailed review of your design and BOM (Bill of Materials), assess DFM/DFT (Design for Manufacturing & Testability), and set up production lines, testing protocols, and material procurement strategies to ensure a seamless transition to full-scale manufacturing.

How do you manage component sourcing and supply chain risks?We work with a vetted global network of suppliers, maintain alternate sourcing strategies, and use real-time inventory systems to manage lead times, availability, and cost fluctuations.

What PCBA services do you offer?We offer both SMT (Surface Mount Technology) and THT (Through-Hole Technology) assembly, including single or double-sided PCBs, BGA placement, reflow soldering, and automated optical inspection.

What PCB technologies do you support?We support single, double-sided, and multilayer PCBs up to 36 layers, as well as rigid, flex, and rigid-flex designs. We also handle HDI and high-frequency boards.

Do you have ESD safety measures in manual zones?Yes, all manual assembly areas are equipped with ESD-safe tools, mats, wristbands, and proper grounding to protect sensitive electronics.

Are your soldering processes RoHS-compliant?Yes, we offer lead-free soldering based on your regulatory needs.

What types of soldering techniques do you use?We utilize selective soldering, hand soldering, and soak soldering, depending on the product requirements and component types.

Is battery safety testing included?Yes, we test for over-voltage, short-circuit protection, thermal behavior, and compliance with international safety standards.

What types of tests are performed on finished products?We perform in-circuit testing (ICT), functional testing (FCT), burn-in testing, environmental stress testing, and customer-specific test protocols.

Unleash Your Potential with Elnux Embedded Systems

Are you ready to elevate your experience to unprecedented heights? It’s time to seize the opportunity that awaits you.

CONTACT US