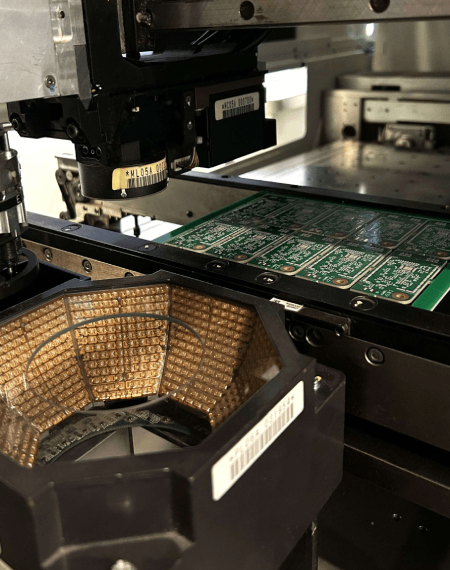

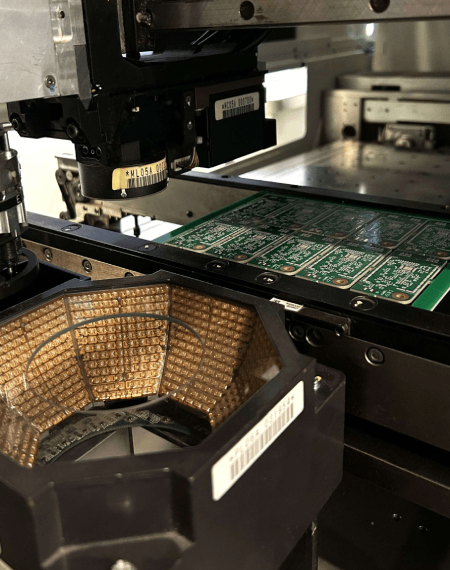

Printed Circuit Board Assembly is the process of mounting and soldering electronic components onto PCBs using a combination of advanced automated equipment. This includes solder stencil printers, SMT pick-and-place machines, reflow ovens, and selective through-hole soldering systems. We follow IPC-A-610 standards throughout to ensure the quality and reliability our customers expect.

Quality control is built into every stage of the assembly process. From start to finish, we monitor for potential issues, address defects early, and make sure every board meets both industry standards and client requirements.

Our core assembly capabilities include:

- Surface-Mount Technology (SMT): Components are mounted directly onto the surface of the PCB, making it possible to build compact, high-density designs that suit today’s sophisticated electronics.

- Through-Hole Technology (THT): Components are inserted into pre-drilled holes and soldered on the opposite side, creating strong mechanical bonds. This method is ideal for parts that must withstand physical stress.

- Automated Optical Inspection (AOI): Using high-resolution cameras and intelligent software, we check each board for soldering accuracy, alignment, and overall assembly quality-catching issues early in the process.

Our Perks

Experience the flexibility of our services with no minimum order quantity, ensuring your custom needs are met with precision and care.

Accelerate your project’s journey into reality with our services short lead time, ensuring swift delivery of quality products to meet your deadlines.

Simplify your experience with our services through friendly customer service, providing seamless communication and support every step of the way.

Extend your peace of mind beyond production with our comprehensive after-sales support in our services, ensuring continued satisfaction and reliability long after delivery.

A wide range of PCBA services

Frequently Asked Questions

What PCBA services do you offer?We offer both SMT (Surface Mount Technology) and THT (Through-Hole Technology) assembly, including single or double-sided PCBs, BGA placement, reflow soldering, and automated optical inspection.

What PCB technologies do you support?We support single, double-sided, and multilayer PCBs up to 36 layers, as well as rigid, flex, and rigid-flex designs. We also handle HDI and high-frequency boards.

What file formats do you accept for PCB assembly?We accept Gerber files, BOMs (Bill of Materials), Pick & Place data, and assembly drawings. We can also assist in generating these files if needed under ODM service.

How do you ensure soldering quality in SMT assembly?We use automated paste inspection (SPI), precision reflow ovens, and AOI inspection to ensure consistent and high-quality solder joints.

Are your soldering processes ROHS-compliant?Yes, we offer lead-free soldering based on your regulatory needs.

How do you prevent cold solder joints?Through precise temperature profiling, skilled technicians, and inspection systems like AOI.

What types of soldering techniques do you use?We utilize selective soldering, hand soldering, and soak soldering, depending on the product requirements and component types.

What is soak soldering and when is it used?Soak soldering involves gradually heating the board to prevent thermal shock and ensure uniform solder flow. It’s used for temperature-sensitive or high-density components where precise control is crucial.

Unleash Your Potential with Elnux Embedded Systems

Are you ready to elevate your experience to unprecedented heights? It’s time to seize the opportunity that awaits you.

CONTACT US