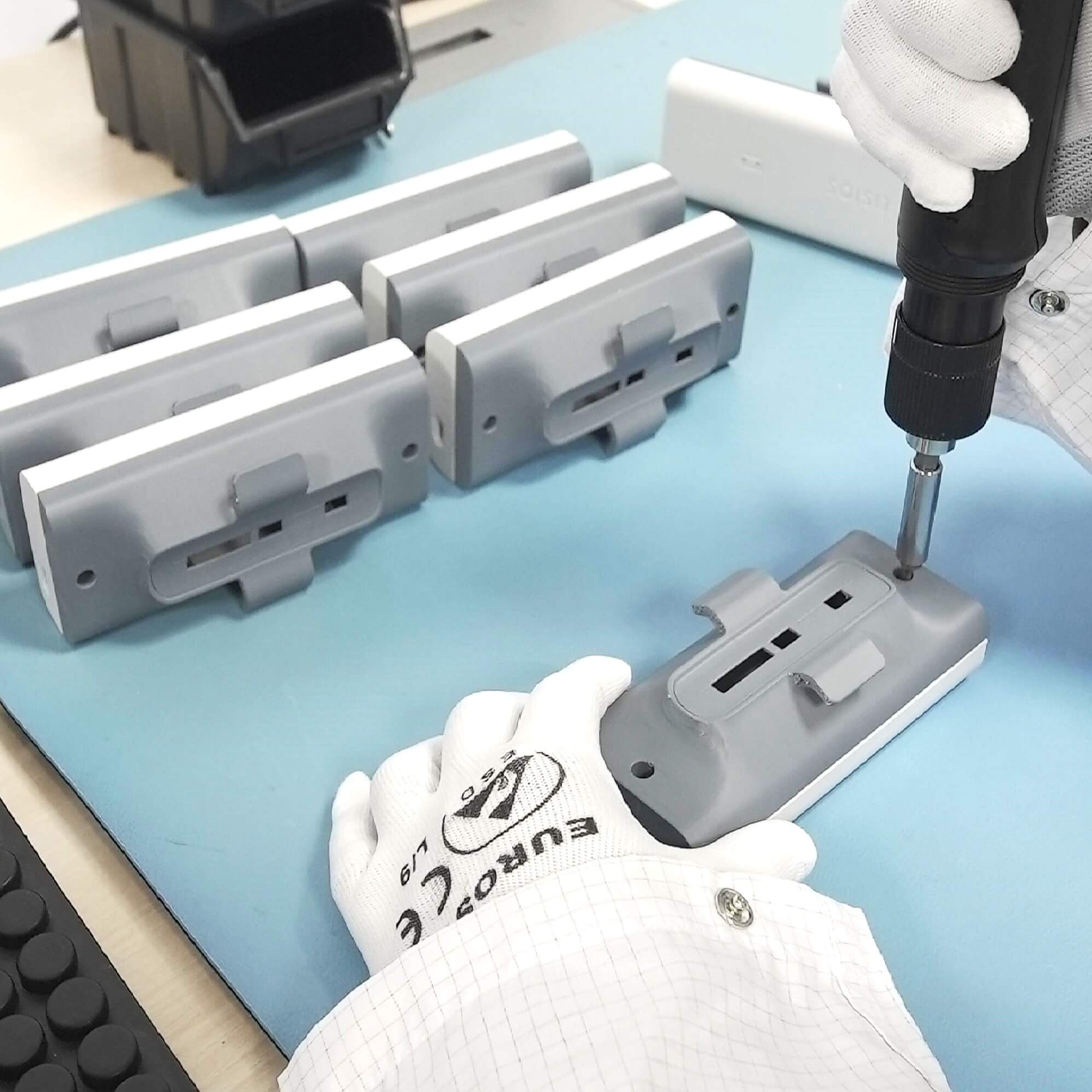

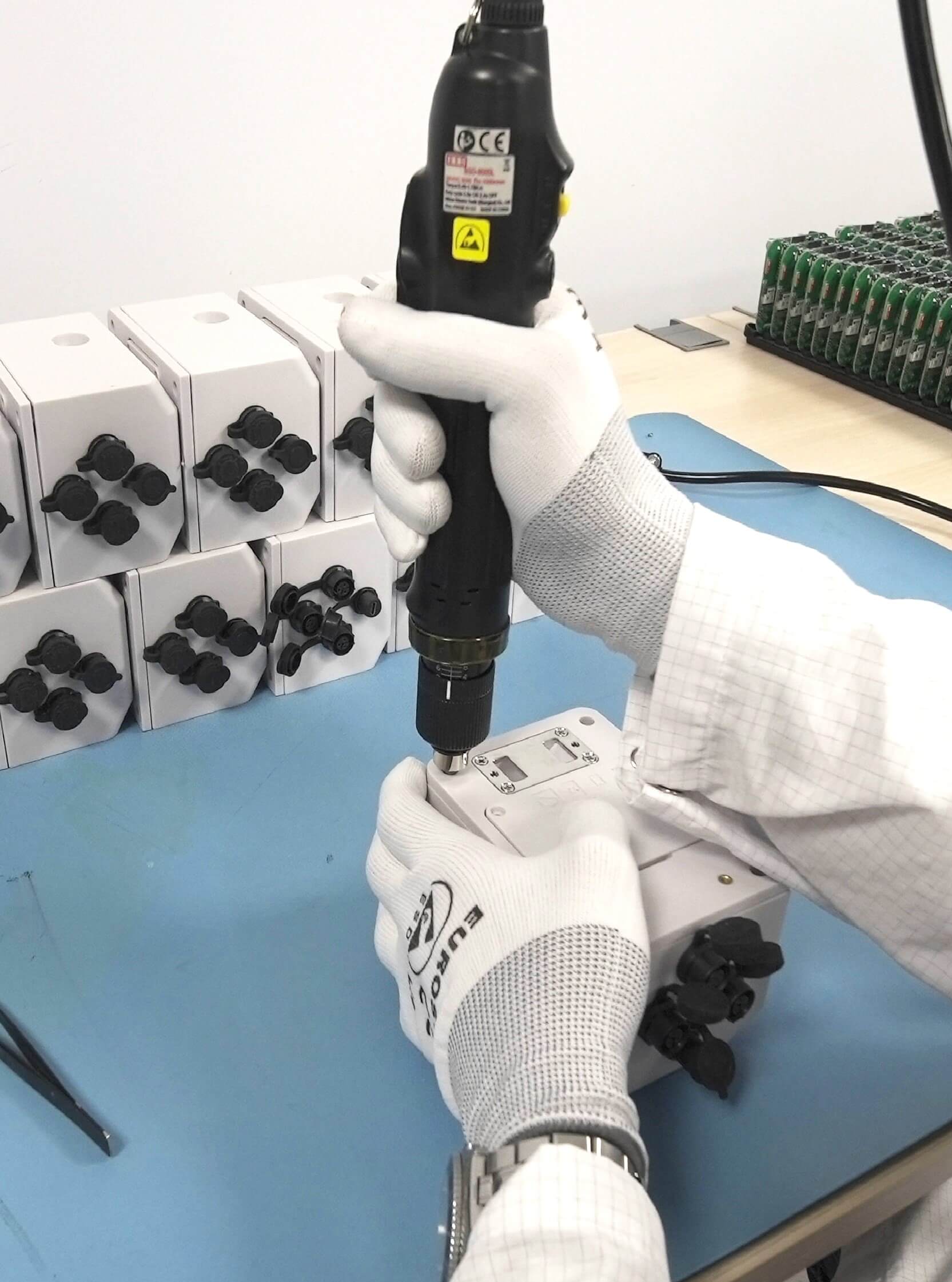

Final assembly is where everything comes together-the point at which individual parts like enclosures, displays, buttons, connectors, and cables are integrated into a complete, working product. It’s a critical step that not only enhances manufacturing efficiency but also improves overall quality control and speeds up time to market.

At Elnux, we take a hands-on approach to optimizing each stage of this process, ensuring every product is built to meet the high standards of a competitive global market. Final product assembly brings real advantages, including:

- Seamless Integration of all mechanical and electronic components

- Thorough Quality Checks to catch issues before products ship

- Final Testing and Inspection to verify full functionality

Our Perks

Experience the flexibility of our services with no minimum order quantity, ensuring your custom needs are met with precision and care.

Accelerate your project’s journey into reality with our services short lead time, ensuring swift delivery of quality products to meet your deadlines.

Simplify your experience with our services through friendly customer service, providing seamless communication and support every step of the way.

Extend your peace of mind beyond production with our comprehensive after-sales support in our services, ensuring continued satisfaction and reliability long after delivery.

Here’s how our assembly process works:

Frequently Asked Questions

Do you provide mechanical assembly alongside electronics?Yes, we assemble the complete product, including housing, connectors, and even final product labeling.

Can you handle customized enclosure designs?Definitely. We work with a range of enclosure options-plastic, metal, or hybrid-and can also assist in custom molding and machining.

How do you maintain quality across final product builds?We implement in-line inspections, final functional tests, and batch audits to ensure consistency and adherence to your specifications.

Can you handle complete product assembly including enclosures and packaging?Yes, we offer turnkey solutions-from PCB integration into enclosures to functional testing, labeling, and custom packaging to get your product market-ready.

Do you have ESD safety measures in manual zones?Yes, all manual assembly areas are equipped with ESD-safe tools, mats, wristbands, and proper grounding to protect sensitive electronics.

Unleash Your Potential with Elnux Embedded Systems

Are you ready to elevate your experience to unprecedented heights? It’s time to seize the opportunity that awaits you.

CONTACT US