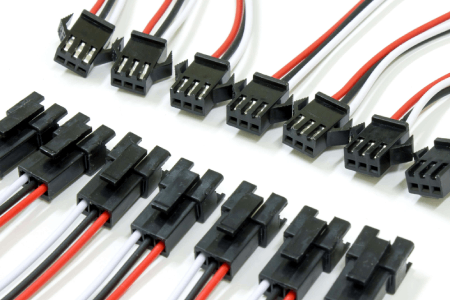

Producing wire harnesses-whether for prototypes or large-scale runs-requires careful design, quality materials, and streamlined assembly to ensure dependable performance. We rely on standardized parts, lean manufacturing methods, and skilled technicians, all supported by strict quality controls. Automation helps speed up processes like wire cutting and crimping, while thorough testing guarantees each harness meets industry standards before it leaves our facility.

Contact Us

Our Perks

Experience the flexibility of our services with no minimum order quantity, ensuring your custom needs are met with precision and care.

Accelerate your project’s journey into reality with our services short lead time, ensuring swift delivery of quality products to meet your deadlines.

Simplify your experience with our services through friendly customer service, providing seamless communication and support every step of the way.

Extend your peace of mind beyond production with our comprehensive after-sales support in our services, ensuring continued satisfaction and reliability long after delivery.

Explore the world of Prototype and Mass Production

Frequently Asked Questions

What information do I need to provide for a wire harness prototype?You should provide detailed specifications, including wire type, connectors, component placement, length, and any relevant diagrams or CAD files. Our team will work with you to refine the design based on your requirements.

How do you handle quality control in mass production of wire harnesses?For mass production, we implement strict quality control procedures at every stage of production. This includes visual inspections, automated testing, and compliance checks with IPC/WHMA-A-620E standards.

What types of materials do you use for wire harness prototypes?We use a wide range of materials for wire harness prototypes, including various wire types, connectors, terminals, and protective insulation, more depending on your specific requirements.Contact us, our expert engineers provide guidance on wire harness. Let us collaborate to power your devices with confidence.

What is your minimum order quantity (MOQ) for mass production?MOQ varies depending on the complexity of the harness and material sourcing requirements. We support both low-volume builds for specialty projects and high-volume production for OEMs. Please contact us with your specifications for a tailored quote.

How do you ensure prototype accuracy and quality?Prototypes undergo manual and automated testing, including continuity checks, connector fit validation, and dimensional verification against customer drawings. Feedback from the prototype is used to refine the design before mass production.

Unleash Your Potential with Elnux Embedded Systems

Are you ready to elevate your experience to unprecedented heights? It’s time to seize the opportunity that awaits you.

CONTACT US