Key Takeaways

- OTA testing is essential for verifying wireless performance in real-world conditions, ensuring devices function as expected.

- From design to production and certification, OTA testing refines devices and guarantees compliance.

- OTA testing addresses challenges like cost and accuracy, and it ensures seamless integration with other systems.

What is OTA?

OTA, or Over-The-Air technology, is a method used to send data, updates, and configurations to devices wirelessly. It is crucial to evaluate the performance of Internet of Things (IoT) wireless devices in real-world conditions. As IoT devices are booming across various sectors, the need for efficient and reliable wireless communication has become increasingly important. That’s where OTA measurement comes in. Over-the-air testing is a method used to evaluate the operating performance of wireless devices.

In this blog post, we’ll explore how an OTA performance test system ensures IoT wireless device efficiency and why it’s crucial for their long-term performance. We’ll also dive into the role of OTA wireless communication and IoT updates in this process.

Why OTA Testing is Essential for IoT Devices

If an IoT device has any performance issues, it can lead to delayed responses, data loss, and device failures. So, OTA (Over-The-Air) testing is essential to evaluate their performance, which directly impacts user experience and the cost of IoT systems.

Here’s why OTA is essential

Reliable Connectivity: OTA testing identifies potential issues with signal strength, range, and interference, ensuring consistent data transmission between the IoT device and the network

Remote Updates: IoT devices often need frequent software updates for new features, bug fixes, or security patches. OTA testing ensures that these updates can be delivered efficiently and safely to devices without the need for physical interaction

Improved User Experience: OTA testing ensures that updates are applied seamlessly, maintaining a smooth user experience

Compliance with Standards: OTA testing is often required to meet regulatory standards for wireless communication, ensuring devices operate within legal parameters.

Understanding OTA Performance Test Systems

An OTA performance test system is a specialized setup used to measure the wireless performance of IoT devices in real-world conditions. It tests the efficiency of OTA wireless communication and evaluates its ability to handle data transfers and IoT updates.

Key components of OTA performance test systems include:

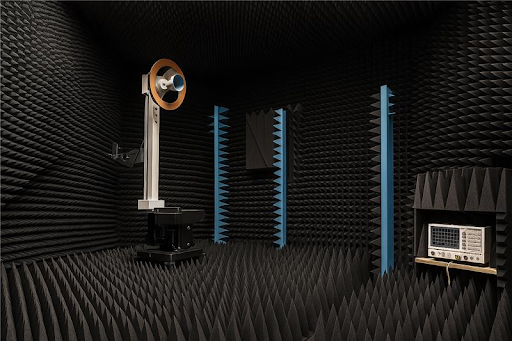

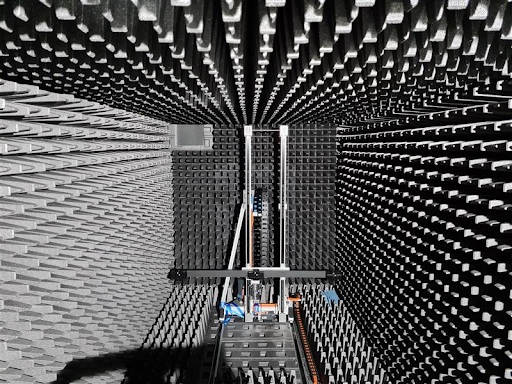

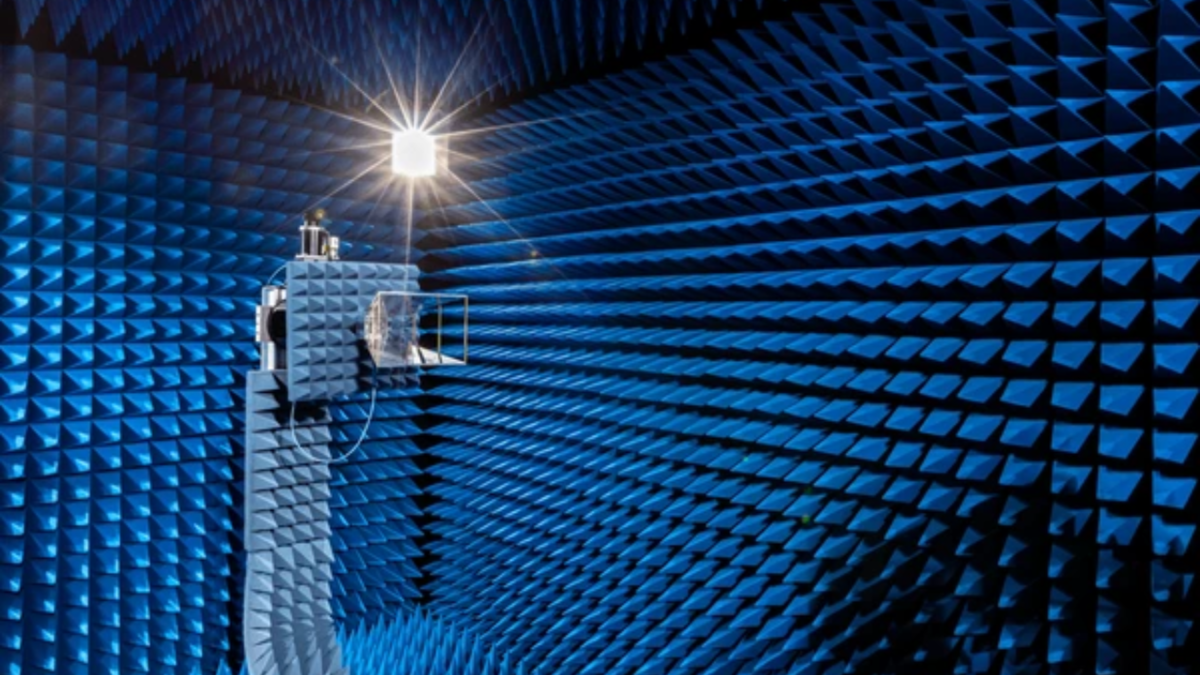

- Anechoic Chamber: A controlled environment that eliminates external wireless interference.

- Measurement Antennas: Devices that capture and analyze signals sent by the IoT device.

- Signal Analyzers: Tools that measure signal strength, quality, and reliability.

Types of OTA Tests Conducted:

- Throughput Testing: Measures the data transfer rate of the device.

- Sensitivity Testing: Evaluates how well the device picks up weak signals.

- Radiation Pattern Testing: Analyzes how signals are emitted and received in different directions.

- Environmental Testing: Simulates conditions like temperature fluctuations, humidity, and interference from other devices to assess how the IoT device handles real-world environmental changes.

- Interference Testing: Testing how the device performs in the presence of other wireless signals to ensure robust communication

How OTA Performance Test Systems Optimize IoT Wireless Devices

Here’s how OTA performance test systems optimize IoT wireless devices:

- Ensuring Reliable Wireless Communication: OTA testing ensures stable and efficient data transmission by evaluating the device’s ability to maintain connections under varying conditions.

- Improving Data Throughput and Bandwidth Efficiency: By assessing the speed and consistency of data transmission, OTA performance tests help optimize bandwidth usage and improve overall network efficiency.

- Reducing Latency and Improving Response Time: OTA testing measures latency levels, ensuring IoT devices can quickly respond to network requests and provide real-time functionality.

- Enhancing Power Efficiency: Since many IoT devices run on battery power or are constrained in terms of energy resources, power efficiency is critical. OTA performance test systems evaluate the power consumption of devices under different operating conditions and network usage scenarios.

- Antenna Efficiency: By measuring the radiation pattern of the antenna, OTA testing ensures the device’s antenna design is optimized for efficient signal transmission and reception across different orientations.

Real-World Applications of OTA Testing in IoT

Here are some real-world applications of OTA testing in IoT:

- Smart Homes and Consumer Electronics: Thermostats, security cameras, and smart assistants rely on OTA updates for new features and security patches.

- Industrial IoT (IIoT): Sensors and monitoring devices in factories depend on strong wireless connections for accurate data transmission.

- Automotive and Transportation: Connected vehicles use OTA technology for software updates and performance enhancements.

- Healthcare: Remote patient monitoring systems, wearable health trackers, and wireless diagnostic equipment need consistent wireless performance for real-time data syncing.

- Smart Cities: Smart lighting, traffic management systems, and environmental monitoring networks need performance evaluations for reliable data collection and efficient operation of city services.

Common Challenges Faced in OTA Testing

While OTA testing is essential, it does come with challenges:

1. Power consumption: Many IoT devices, particularly wearables and remote sensors, rely on limited battery power. OTA testing needs to evaluate how updates and wireless communication impact power consumption.

2. Interference from other devices: IoT devices often operate in crowded wireless spectrums, where interference from other devices (e.g., Wi-Fi routers, Bluetooth devices, microwave ovens, etc.) can affect their communication performance. This can be challenging to replicate in a controlled environment.

3. Environmental factors: IoT devices deployed in varying environmental conditions may experience reduced performance or failures if not properly tested under different weather conditions or physical obstructions (walls, metal structures, etc.).

4. Network Bandwidth Limitations: OTA updates require significant network bandwidth, and many IoT devices are deployed in areas with limited connectivity (e.g., rural areas, remote locations, or low-coverage areas).

5. Firmware version management: IoT devices may require the ability to handle multiple versions of firmware and software updates over time. Managing version compatibility between different firmware versions and ensuring backward compatibility can be complex.

Conclusion

OTA measurement is essential for ensuring the seamless performance of IoT wireless devices. By using an advanced OTA performance test system, manufacturers can enhance device reliability, improve user experience, and ensure smooth IoT updates.

If you’re looking for cutting-edge OTA testing solutions, Orbis Systems offers the expertise and technology you need. Get in touch today to learn more about their comprehensive testing services.

FAQs

- How often should OTA testing be performed on IoT devices during their lifespan beyond the initial production and certification phases?

“Over-the-air (OTA) testing for IoT devices should be performed periodically throughout their lifespan, beyond the initial production and certification phases, to ensure continuous functionality, security, and performance. Regular testing, typically quarterly, semi-annually, or when significant changes are mad,e is essential to ensure the device continues to operate as expected throughout its life.”

- What are the implications of emerging wireless technologies like 5G or future 6G standards on current OTA testing methodologies and equipment?

- OTA testing equipment needs to be upgraded to support higher frequencies and to test devices operating at higher bands.

- The speed and efficiency of OTA updates needs to be tested in both high-traffic environments and in low-signal conditions

- OTA testing needs to incorporate these new communication protocols and standards into test scenarios to ensure compatibility and successful updates across a wide range of network configurations

- Interference and network congestion testing will be more important, as the high number of devices on a network could affect the success of OTA updates

- How do geographical location and varying environmental conditions impact OTA testing results and required testing parameters?

Geographical location and environmental conditions have a significant influence on OTA (Over-the-Air) testing results for IoT devices. These factors impact signal propagation, device performance and network coverage

Environmental factors can significantly alter signal propagation. Tests should simulate these conditions, and parameters should be adjusted to reflect real-world deployment scenarios.

Hence, testing must consider different network topographies, weather conditions, interference levels, and mobility scenarios to ensure that devices perform reliably in the real world.

- Are there specific security protocols or encryption methods that should be tested within OTA testing to ensure the integrity and confidentiality of data transmitted by IoT devices?

Yes, Security testing must verify protocol effectiveness and encryption strength under various signal conditions. This ensures data integrity and protects against potential vulnerabilities.

- For IoT devices that use multiple wireless communication protocols, how are these protocols integrated and tested within a single OTA testing setup?

To integrate and test multiple wireless communication protocols within a single OTA (Over-the-Air) testing setup for IoT devices, a dedicated testing platform is typically used. Multi-protocol testing requires specialized equipment that can simultaneously measure and analyze different wireless signals. Test setups must account for potential interference between protocols.